Products

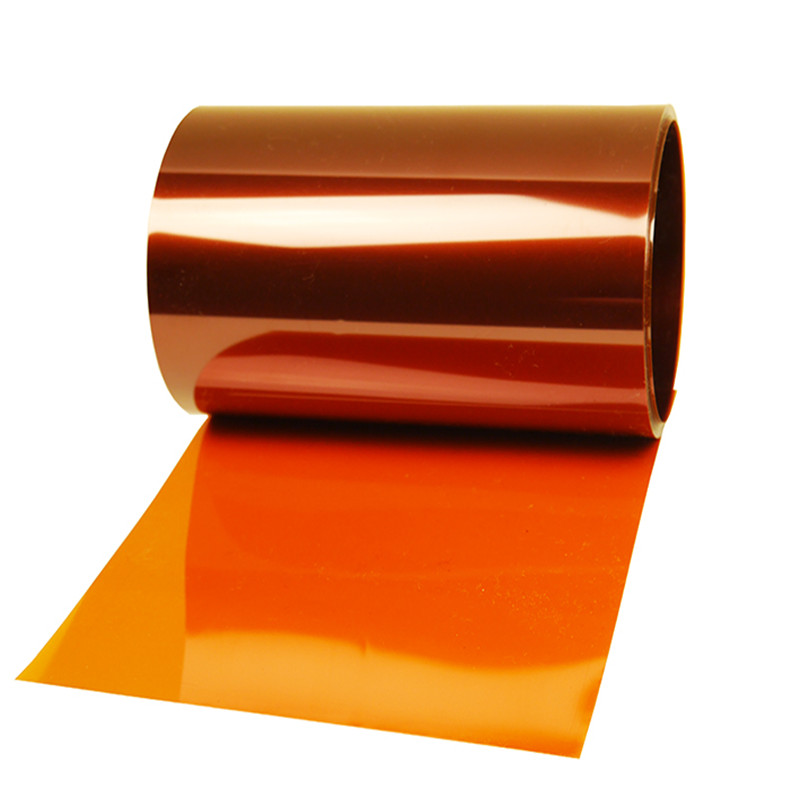

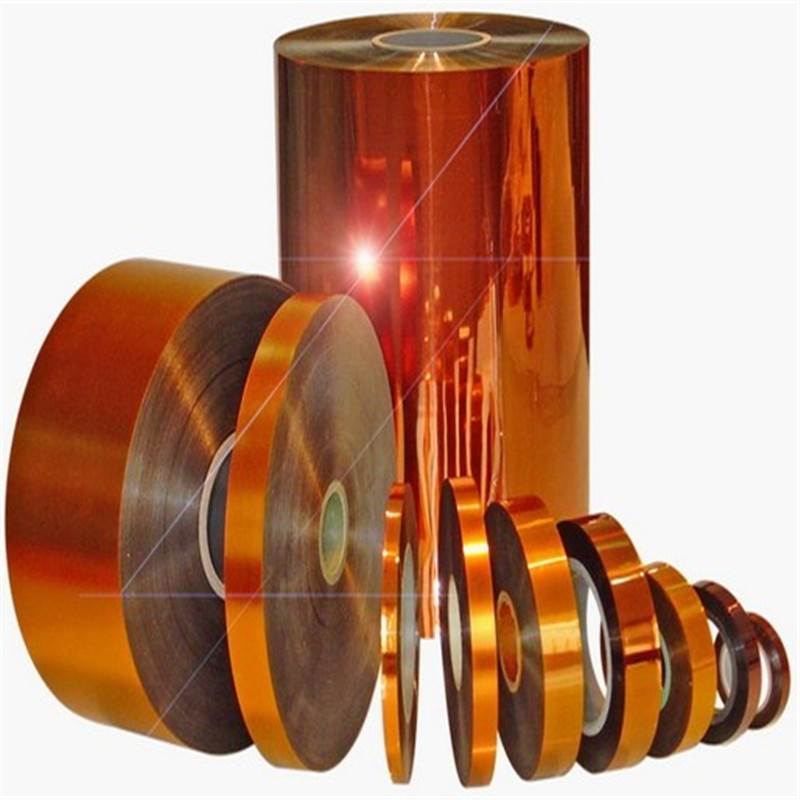

High Temperature Kapton Polyimide Film Tape For Masking Insulation Sublimation

- Customized: Available

- Free Sample: Available

- Certificate: SGS, UL, ISO

- Product description: Kapton Polyimide film (PI film) provides high degree of resistance to chemicals and excellent outgasing properties in high vacuum environments.

High Temperature Kapton Polyimide Film Tap For Masking Insulation Sublimation

Product Description

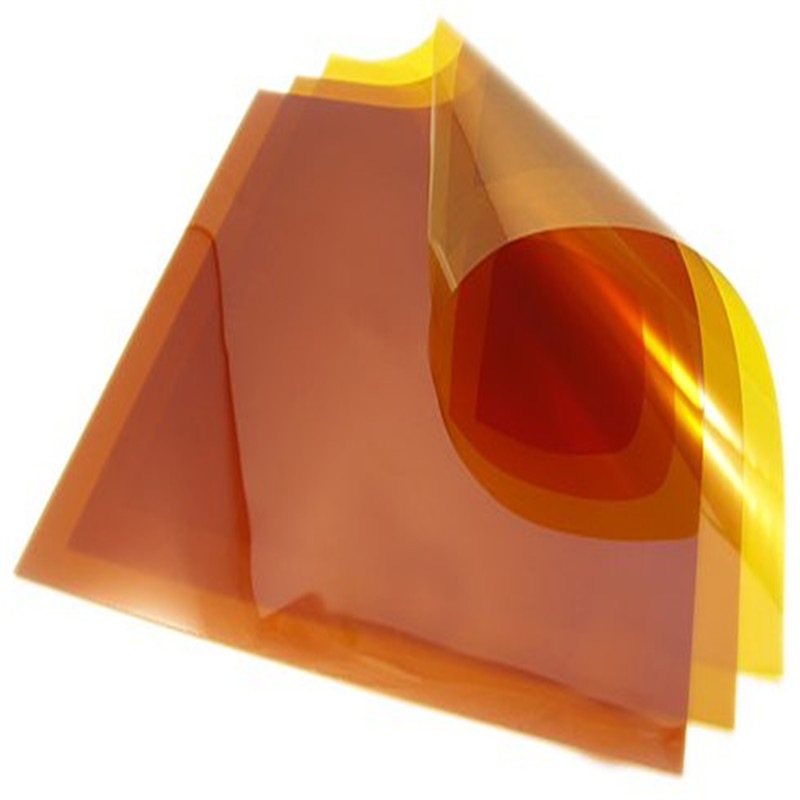

KZ-6051 polyimide film is made of PMDA 4-formic acid-2-anhydride of benzene (PMDA )and 4.4-diamino-diphenyl-ether oxide (ODA) in film casting machine and then stretched by two directions.

Properties

Excellent performance of mechanism and electric

Excellent flame retardant property

High temperature resistant: -269℃ (-452.2 F) - +260℃ (492 F), up to +400℃ for short working time

Excellent chemical resistance. Resistant to freon and most organic solution, no corrosion made by any inorganic acid and alkali except for caustic alkali

Excellent radiation resistance

Moisture protection and corrosion resistance

Applications

Wrapping electromagnetic wire and high temperature cable

H-class insulation in Motor, transformer, capacitor

Nuclear industries

Substrates of Flexible Printed Circuits Board (F-PCB)

Backing materials of pressure-sensitive adhesive tape, F46 (FEP) tape, polyimide tube.

Specifications

|

NO |

Index description |

Unit |

Index Value(KZ-6051) |

||||||||||||||

|

1 |

Standard thickness |

µm |

25 |

40 |

50 |

75 |

100 |

125 |

175 |

200 |

|||||||

|

2 |

Allowable tolerance |

µm |

+4 |

+6 |

+7 |

+8 |

+10 |

+8 |

+8 |

+8 |

|||||||

|

3 |

Density |

Kg/m³ |

1420±20 |

||||||||||||||

|

4 |

Tensile |

Longitudinal |

Mpa |

≥135 |

|||||||||||||

|

5 |

Elongation |

Longitudinal |

% |

≥35 |

≥50 |

≥50 |

|||||||||||

|

6 |

Hot- |

150℃ |

% |

≤1.0 |

|||||||||||||

|

7 |

Frequency |

Average value |

MV/m |

≥150 |

≥130 |

≥110 |

≥100 |

≥100 |

|||||||||

|

8 |

Volume resistivity at 200℃ |

Ωm |

≥1.0×1010 |

||||||||||||||

|

9 |

Surface rssistivity at 200℃ |

Ω |

≥1.0×1013 |

||||||||||||||

|

10 |

Relative dielectnic constant |

- |

3.5±0.4 |

||||||||||||||

|

11 |

Dielectric dissip ation factor |

- |

≤4.0×10-3 |

||||||||||||||

|

12 |

Long tenm heat resist ance |

℃ |

≥380 |

||||||||||||||

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Anthony Li

Phone: +8618750270393

Tel: 0592-7075788

Email: sales2@aerchs.com

Add: Room 201, NO 91, Tian'an Road, Jimei District, 361021, Xiamen, China

polyimidefilmtape

polyimidefilmtape Anthony Li

Anthony Li